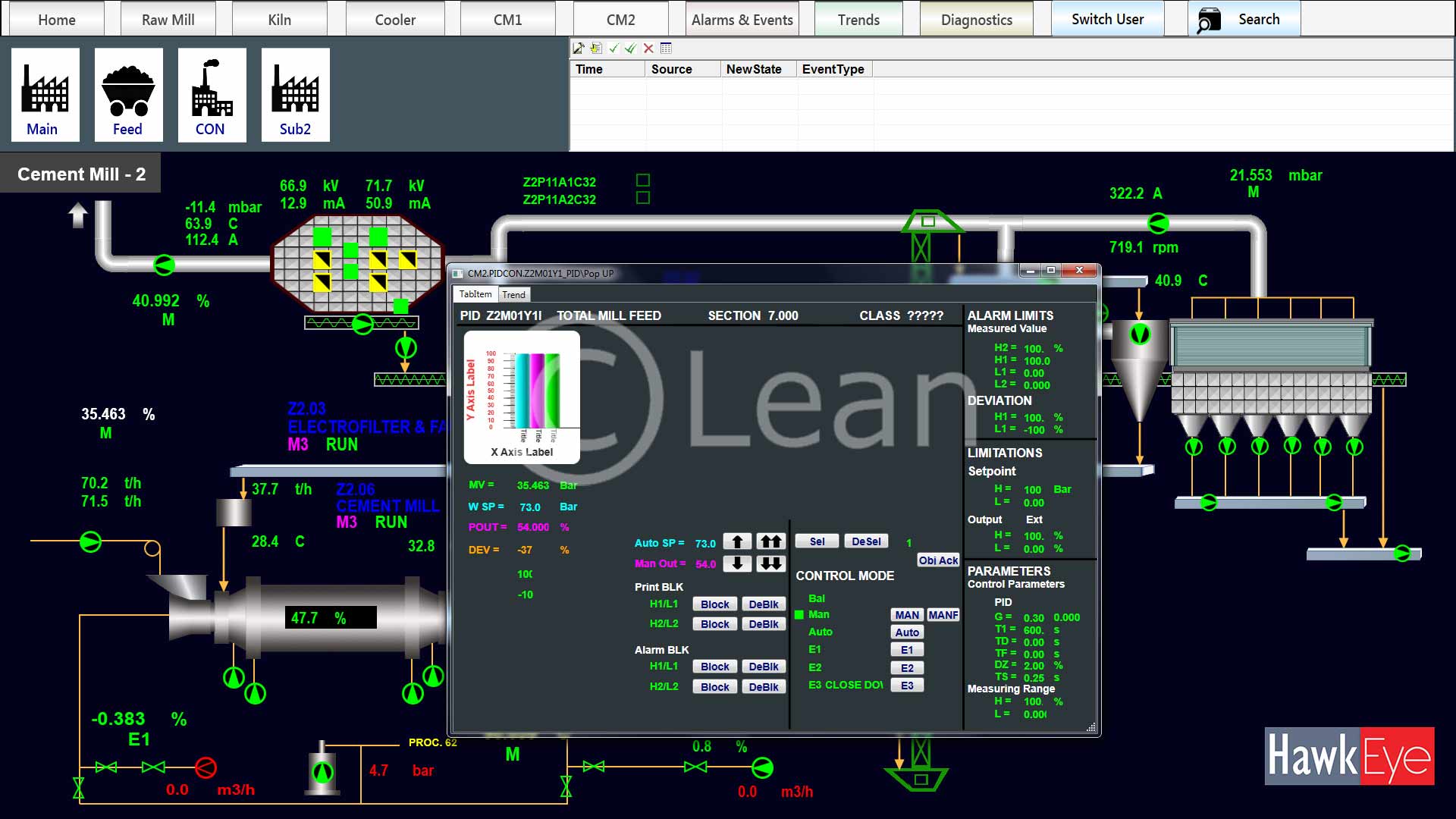

HawkEye™ represents a quantum leap in HMI/SCADA technology with stunning 2D and 3D hardware-accelerated visualization. HawkEye™ is a one-stop-shop HMI solution demanding rapid application development, powerful features, scalability, robustness, optimal intuitive user interface and reduced total cost of ownership.

HawkEye™ is built on and integrated with a single, open and scalable software architecture that can connect to virtually any automation system, remote terminal unit (RTU), intelligent electronic device (IED), programmable logic controller (PLC), database, historian or business system in use today. The open nature of this platform enables users to expand their existing systems without having to buy new hardware or control systems to use in almost every industry.

Benefits

Easy to use and easy to implement

Easy configuration and simplified maintenance

High security and availability

Virtually unlimited scalability

Implement Smart Client deployment with 100% managed components.

Extremely fast data update with very low CPU usage.

Very cost effective solutions for both individual and corporate users.

Fast development time with no code required.

Use your own data from .NET applications.

Open Database Format

Extremely Less Bandwidth Footprint over communication networks.

Template-based development and maintenance

Data collection and analysis for new and existing systems

Easy-to-use report generation

Open access to historical data

Features

- 32 bit (Legacy) and 64 bit HMI Applications

- Thick (Native), Web-based and Smart Client Technology Support

- 3D Visualization

- Windows Presentation Foundation (WPF)

- Built on WCF Technology; say no to DCOM!

- Design time tightly integrated with Visual Studio 2012 and Expression Blend 3

- Control and modify Tag, Data Logging, Alarm Logging, Alarm Notification, Recipe, Report, and Security configurations with few clicks using highly intuitive interface.

- Ultra Fast Built-in Data Logger; Store data as fast as 100 Nano seconds.

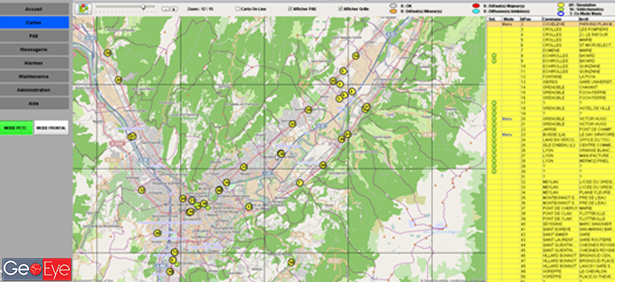

- Built-in APIs for integration with Microsoft Bing Maps

- Log your HMI data in any Database; Oracle, Microsoft SQL, My SQL, CSV…

- Excel, PDF, Web-based static and dynamic reporting

- 21CFR11 compliant Event Handling

- EEMUA191 and ISA 18.2 Alarm Management and Analytics

- OPC Classic and OPC UA Compliant.

- 350+ communication protocols like Modbus, Profibus, CIP…

- OBDC, OLEDB, WCF and CSV compliance for data exchange with any 3rd party applications