Lean Enterprise Manufacturing Intelligence solution translates manufacturing data from the plant-floor into actionable intelligence for decision makers at the enterprise and business level.

Our Manufacturing Intelligence suite of solutions enable users to overcome business challenges, resulting in increased profitability, streamlined business efficiency and a strengthened loyalty to customers and vendors.

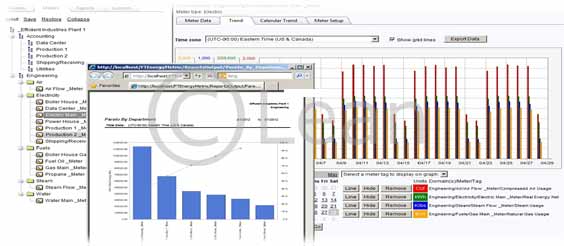

Lean EMI allows you to collect manufacturing-related data from across your plant, transfer it to your business systems and use it to create reports, analyses and visual summaries. Manufacturing Intelligence strategies leverage a suite of reporting and analysis tools, interfaces and dashboards designed to deliver contextual, localized, role-based information to help you improve your process. When given new structure or context, these data allow users to easily find the information they need, regardless of its source. This real knowledge drives business results across the enterprise. And our Technologies will help you to make it happen.

Lean EMI performs five core functions: aggregation, contextualization, analysis, visualization and action. For this purpose, our EMI solutions correlate data from a variety of sources; data regarding quality, manufacturing, and inventory. So you can analyze it and make timely decisions. By delivering the right information to the right people at the right time, our solutions enable real-time decision making on the shop floor while supporting long-term continuous improvement initiatives.

For large manufacturing operations with multiple plants even in different locations, Lean EMI solution addresses needs from planning to production, quality assurance, maintenance, asset and inventory management.

Help to Manufacturer

- Combining multiple sources of information in the same report allows you to discover trends across disjointed systems in real-time.

- With full time automated operation, reports are delivered with the right information to the right person at the right time.

- Shortens the implementation time for greater return on investment and lowers total cost of ownership for multiple industries and applications.

- Enables more efficient interaction with data to quickly get to the root cause of problems.

Benefits

- Reduce costs

- Optimize production capabilities

- Conserve energy (Reduce Energy Consumption)

- Minimize waste

- Bolster best practices and regulatory compliance

- Aggregate manufacturing information across all assets and resources

- Reduce demand forecast errors

- Assure customer commitments and satisfaction

- Shorten product development and launch cycles

- Monitor production variants

- Enhance overall product quality

- Overcome asset constraints

- Maximize resource utilization